Cold Metals Lab

Turn metal stock into chips with access to saws, mills, lathes, benders, presses, and more.

Cold Metals Lab Overview

In-house technical staff can provide support for iterative prototyping, technical training sessions, or small volume production runs. mHUB creates a welcoming space to prototype and iterate quickly with various 3D printing technologies ideal for cost-effective, low-volume production.

[Cold Metals] General Information

Cold Metals:

Where we turn stock into chips

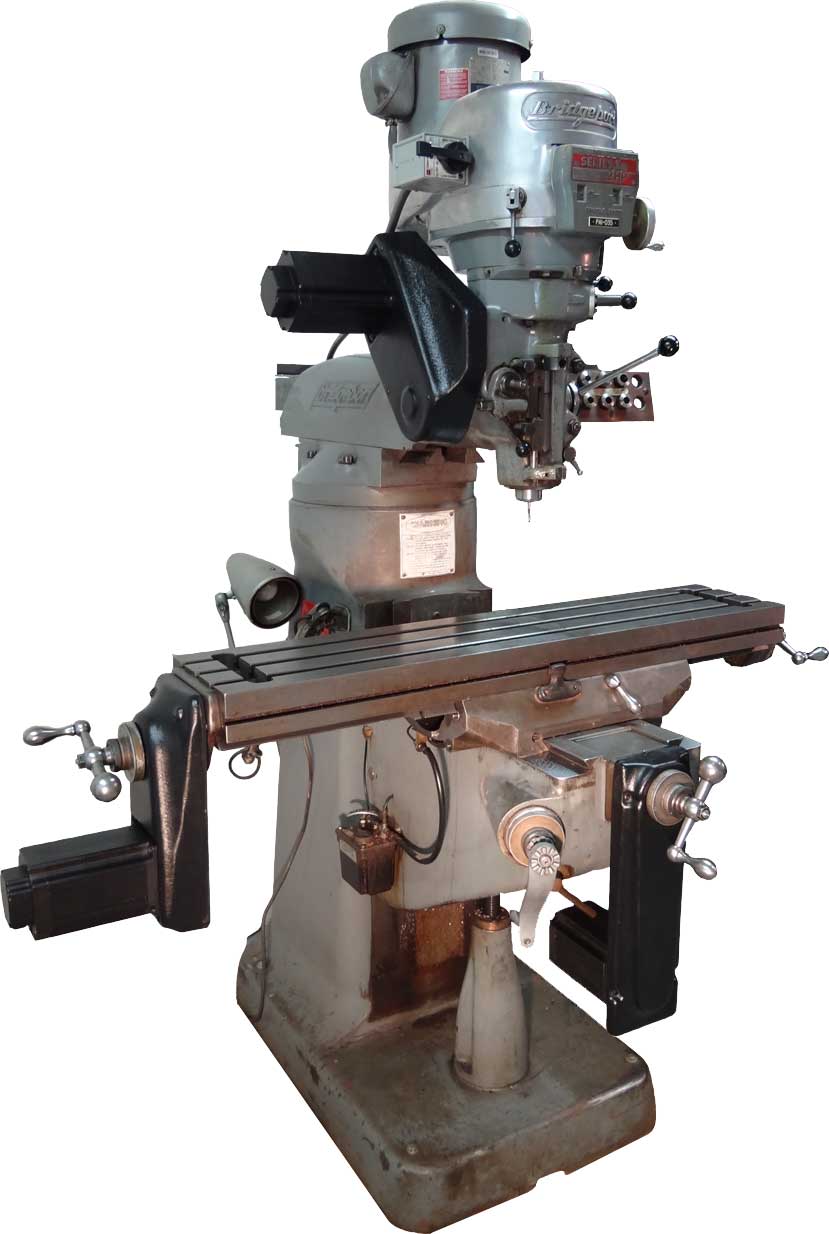

Bridgeport Knee Mill

Bridgeport Knee Mill

no DRO

Drill Bit Sharpener

3/32" to 3/4" bits

115 to 140 degrees

split tip grind guide

Drill Press

Table Swing 20"

1 HP

9 speed settings 150-2200 RPM

25.5" Draw

5" spindle travel

13" x 15" table

Enco Knee Mill

42" x 9" bed

XYZ Digital Read Out

Finger Brake

Quickly bend straight sheet metal forms

Hardinge HLV-H Tool Room Lathe

9" swing over carriage

1HP

125-3000 RPM

quick change tool post

manual collet closer

Horizontal Band Saw

No material less then 1/2" thick

No Wood

10" height max 18" wide

4 setting 80-330 SFM

Horizontal Press

Max. Material Thickness: 1/2" Harden Steel

Max. Material Width: 6"

Hydraulic Iron Worker

Min. Punch Daimeter: 3/16"

Max. Punch Diameter: 1" 1/16"

Angle Iron Sheer

Max. Flat Sheer Material Thickness: 1/2"

Notcher

Hydraulic Shear

Max. Width: 48"

Max. Thickness 12 Gauge

Hydraulic Shop Press

40ton Pressure

36" Brake

Max. Thickness: 1/2"

Hydraulic Tube Bender

10 ton Bending Pressure

Interchangeable Dies

Jonsen Swing-Arm Deburring Machine

vacuum work holding

sanding pad or scotch brite medium

Langmuir Titan 25T CNC Press Brake

CNC back gauge

up to 10ga sheet

Tapping Arm

Tap from #4- 1/2"

40" swing

Reaming & Deburring

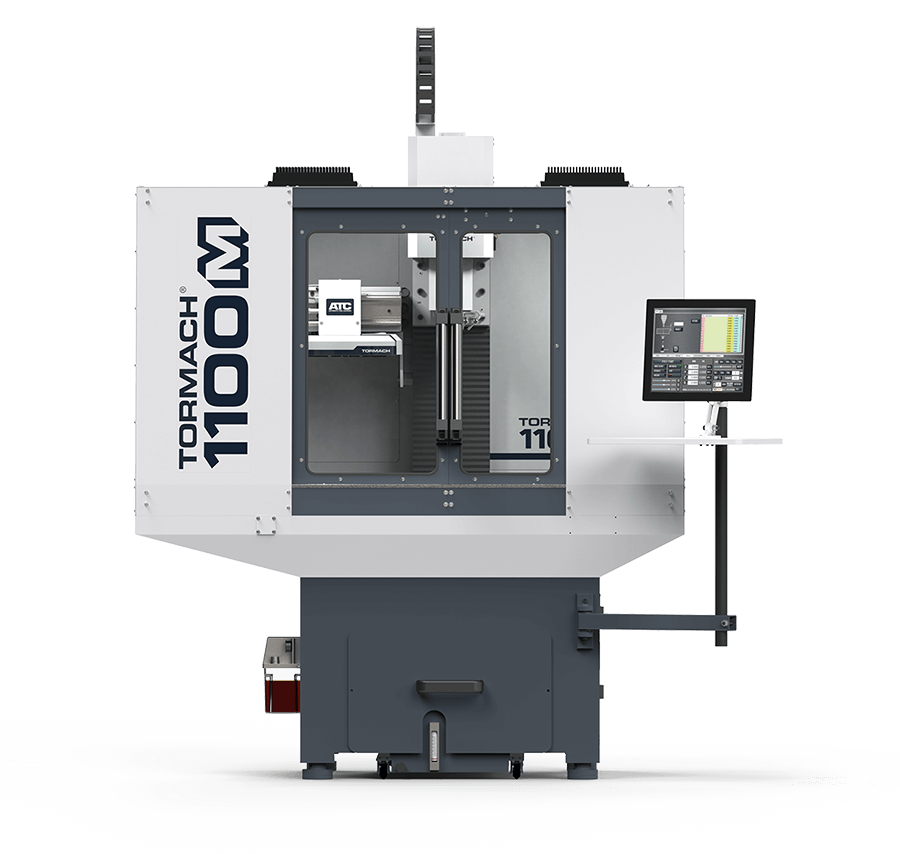

Tormach 1100M

18" x 11" Working area

2HP

110 IPM

7500 RPM

12 ATC

ETS Tool setter

Flood/mist/air coolant and chip evac

Tormach 1100MX

18"x11" working area

2HP

300 IPM

10,000RPM

ETS Tool Setter

Flood/mist/air coolant system

Tormach 15L Slant Pro Lathe

6.2" Swing over carriage

3HP

100-3500 RPM

8 ATC/3 Gang plate/quick change tool post

Automatic collet closer

Bar puller

Rigid tapping

Vertical Band Saw

.25" or less stock

20” x 20” Bed Size

Tilt deg: 8 F & B, 12 L & 15 R

82-330 SFM

Tour the Prototyping Lab

Come see the 11 prototyping labs for hardtech product development. Schedule your visit today!