Manufacturers are focused on their core business and taking care of their customers while they navigate global disruption. It’s easy to understand why Manufacturers need support for product innovation and manufacturing process improvements during this time when manufacturers are being asked to produce more with less.

“This is a time when manufacturers are needing more support than ever to supplement their internal teams,” explains Nick Stagl, Program Manager with mHUB Hardtech Development Services. “Manufacturers typically need industrial designers, fabrication specialists, metallurgists, and experts in finite element analysis (FEA) and computational fluid dynamics (CFD). Meeting this need is often why manufacturers partner with mHUB Hardtech Development Services – so they can tap into mHUB’s diverse talent pool, even as they work to fill skilled workforce gaps in their internal teams.”

In a report released October 8th by the U.S. Bureau of Labor Statistics, manufacturing employment continued to rise at the end of the third quarter, with the industry recovering 1 million of 1.4 million jobs that had been lost during March and April 2020. Even with the hiring improvements, the lag in speed to get new products to market is a real issue for small- to medium-sized manufacturers.

“If it takes 9 to 12 months, for some, that’s too long,” declares Stagl, an experienced mechanical engineer leading the vision and mission of the mHUB Hardtech Development Services team in Chicago. mHUB, the nation’s leading independent manufacturing innovation center, exists to convene the entrepreneurial ecosystem around physical product innovation to ensure that the manufacturing industry continues to accelerate, grow, and thrive.

“If it takes 9 to 12 months, for some, that’s too long,” declares Stagl, an experienced mechanical engineer leading the vision and mission of the mHUB Hardtech Development Services team in Chicago. mHUB, the nation’s leading independent manufacturing innovation center, exists to convene the entrepreneurial ecosystem around physical product innovation to ensure that the manufacturing industry continues to accelerate, grow, and thrive.

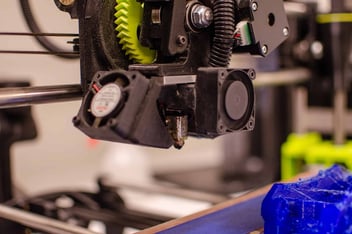

“One of the reasons mHUB Hardtech Development services was created is to support manufacturers with rapid prototyping, and in effect, shorten the time it takes to get products to market.”

Behind the scenes, some manufacturers can struggle with the process for R&D and new product design or development. Having professionals with backgrounds in consumer electronics, IoT, commercial / industrial equipment and automation, manufacturers collaborate with the team at mHUB Hardtech Development services to clearly define processes, quickly support R&D, plan & execute production line process improvements, and problem-solve unique challenges.

“Workload can be a challenge,” continues Stagl, who is currently working to connect manufacturers to mHUB’s talented industry experts to help drive product development and innovation across the manufacturing sector. Manufacturers are often so busy supporting their existing product line and customers that they don’t have time to improve their existing products or develop new products. Factor in the supply chain issues, and there’s a real need for an innovative, ‘outside-in’ approach.

The professionals working with mHUB Hardtech Development services can comprehensively support R&D, design thinking, concept development, customer insights, rapid prototyping and the iterative process of physical product innovation. The entrepreneurial community leveraging the mHUB prototyping lab and micro-factories successfully deliver projects from concept and design to prototype and production.

“mHUB is different from design firms,” declares Nick. “With everything at their fingertips, manufacturers who become part of the mHUB ecosystem find they don’t need to collaborate with multiple firms – all of their corporate innovation can be done right here with mHUB.”

mHUB is a resource that manufacturers can leverage to make process improvements and innovate newer, better products that meet customers’ needs. mHUB oversees and coordinates innovation teams on behalf of clients through its in-house Hardtech Development services department.

Submit the form below if you have any questions related to R&D, product development, operational efficiency, or hardtech innovation.