What an Early-Stage Startup Needs to Know About Contract Manufacturing

If you’re bringing a new product to market and don’t have an in-house manufacturing capacity, you’re going to need to hire a contract manufacturer. Contract manufacturing is when a company hires a manufacturer to build a part, component, or entire product on its behalf.

If you’re a new startup or small business, vetting and finding the right contract manufacturer is largely based on how much you’re willing to spend and the capabilities they have. This article will arm you with the information you need to find a contract manufacturing partner and will cover:

- How to understand capabilities

- How to request quotes

- Planning for and building tools

- Understanding manufacturing timelines

- Running an initial test batch

But first, let’s talk about something important to this process: design for manufacturing (DFM). DFM means you approach product development with manufacturability at the forefront.

Principles of DFM During Prototyping

As a rule of thumb, when developing a new product, it’s best to start thinking about DFM early in the product design stage. For the hardtech and hardware startups, it can be difficult to balance this when bringing a totally new product to market and moving fast to understand the customer and reduce your time to market. When dealing with a physical product, most of this understanding comes through customer testing and deploying iterative prototypes to validate specific features and reduce cost.

On the flip side, if you test a feature that’s well received and find out later it’s too costly or relies on a part that you can’t consistently source as you scale, you’re back to the drawing board with a whole bunch of time wasted. Everything about your product could be so right from a customer standpoint, but if you can’t build it, your business case goes out the window.

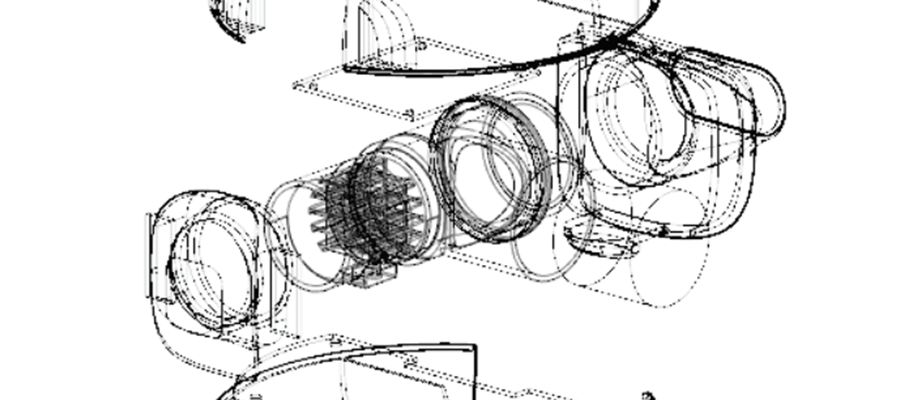

You don’t need to know a lot, but you need to know enough about which process will make each component. Once you pick a method, you can look for design guides that outline those processes. These guides will tell you what shapes and adjacent processes should be used.

Using basic calculations to answer simple questions like these will tell you what you can and cannot do with your product – keeping you aligned with the manufacturing process every step of the way.

Eventually, you’re going to end up with something that resembles less of an MVP and more of a final product. Investors will want to know and see how something will work in a real-life scenario. They’ll want to know how much it will cost to manufacture, which will impact your CAP table and potential revenue. So you’ll get to hiring a contract manufacturer.

If along the way you’ve been keeping DFM in mind, you already have a list of requirements, specs, and documentation to get you started.

What to Consider When Researching Contract Manufacturing Partners

Before reaching out to contract manufacturing partners, you’ll want to answer a few basic questions:

- Do you have a budget in mind? How much do you plan on selling your product for and how big do you want your margins to be?

- What type of capabilities are you looking for: injection molding, metal, sheet bending or stamping, extrusion, CNC machining, forming, electronics assembly, assembly of components, etc.?

- What kind of volume will you be manufacturing?

Once you have these questions answered you can start researching to build a short-list of contract manufacturers to consider. This research should include an understanding of the volumes they work with. What is their minimum ordering quantity (MOQ)? And can your business model support this? Do their capabilities match your needs?

You might also be considering sustainability goals. How important is it that your contract manufacturing partner is committed to reducing its carbon footprint?

Overseas you’ll find more integrated suppliers, doing more parts of the process. They’ll work with sub-contractors to do specialized work, but the contract manufacturer will do the most important parts: assembly and quality control as well as packaging. The contract manufacturer will also do the ordering of parts. Domestically you’ll find more specialized partners and may need to ship to an assembly house.

As a startup or small business, look for someone who can support you early. It’s a plus if they can handle your growth, but you don’t want to be small potatoes to a manufacturer. It’s always a possibility that you’ll need to switch contract manufacturers down the road.

How to Start a Contract Manufacturing Relationship

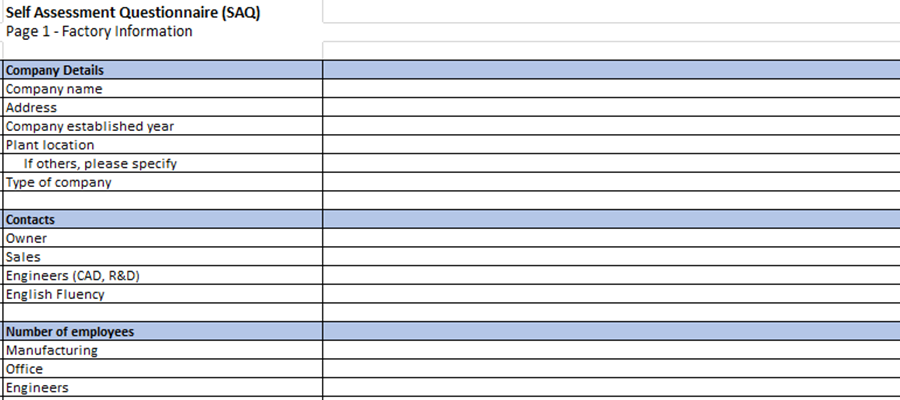

To start vetting manufacturers, have them fill out a contract manufacturing survey. Ask them about process, customers, volumes, and quality control. While you will have already done your research, this makes you look like you have a formal process and also respects everyone’s time by not having them quote something that isn’t a good fit or cost effective.

Most manufacturers will have a sales team. Once you decide who to gather quotes from, what will they need? They’ll want to see a drawing and STEP format CAD files with dimensional specs and tolerances as well as critical features called out. They’ll want to know quantity and what other mating parts there might be. It can also help to share your vision to get them excited by the partnership.

You’ll usually want to ask for a quote that include 3x your original quantity: 100 and 10,000, for example. This will give you a range to help prepare for growth. Quotes can take up to a week to three weeks to receive.

Each manufacturer has its own equipment and manufacturing process, so when it comes down to specific details specific manufacturers might have the ability to handle those and others might not or it’s too expensive. So shopping around is important. There is no single right or wrong way to do things when it comes down to special details, some manufacturers let you break the rules more easily than others. The vendor is going to give you the right answers for them, but a different manufacturer may have a different option.

What to Expect Once you Select a Manufacturer

Once you select a manufacturer, you’ll likely start the conversation of tools. If you’re manufacturing in quantity, manufacturers will request a customized tool be built that can be used over and over again to spit product out quickly. The tooling stage could take 4 – 6 weeks domestically and 3 weeks overseas. It can be capital intensive. Typically, as a startup, you’ll need to have raised money to pay for tooling costs.

Before anything is built, your contract manufacturer will send you an initial batch of parts. This can be 2 weeks domestically and 1 week overseas. They’ll send individual parts to make sure they meet dimensions in the drawings and that they can fit together in assembly. You’ll want to do this initial assembly and might even assemble the first 100 units to create an assembly guide, documentation, and testing procedure. If you’re working on a smart device, you might also need to install the firmware as part of assembly testing and then run through an automated testing jig. PVT, EVT and DVT come into play here.

You could also do this process ahead of hiring a manufacturer, using prototype parts rather than parts from a manufacturer. The value here is that you could create a video or test run to see how long assembly takes, both of which could be reviewed and considered as part of the quoting process.

Either way, you’re going to assemble and review parts from your manufacturer at some point, and it’s common for startups to even package and ship their initial batch to customers.

But let’s circle back to firmware for a moment. If you do high volume, you can order microprocessors with firmware or a boot loader already installed. This requires a software that would allow you to push an over the air update. When the component is powered up for the first time, it gets the latest firmware. This could happen at either the manufacturer or with the customer.

If it’s not a connected product (meaning it doesn’t’ use wifi or Bluetooth) you can either order chips that are preprogrammed from another manufacturer (you would give them the firmware, and they would upload it) or your contract manufacturer would upload it during assembly and quality control testing. Either way, you have a circuit board component and flash firmware onto it.

Once you get your initial batch of parts and test assembly, you’ll want to visit the manufacturer to watch their assembly process and quickly iterate the process based on both of your assembly findings, rather than ship things back and forth. This could even be done when the first parts are coming out to tweak parameters on site to make sure they fit with required tolerances.

You’ll predetermine with the manufacturer if you want the product shipped to you direct where your team then handles shipping or if it ships to a warehouse where you contract an entity to handle shipping. When you start shipping, customers might report product failures due to different environments, temperatures, or cutting corners, etc. It’s common that you might need to continue to make tweaks ahead of manufacturing your next batch. This could even require new tools or modifications to tools or new parts, so plan ahead for that unknown.

At this point it’s about staying in front of your contract manufacturing partner while your product volume is low. You may decide to increase the size or number of your tools as demand increases, and it’s always smart to stay on top of ways to reduce the cost of manufacturing.

Let’s Review What You’ve Learned About Contract Manufacturing

Wow. That’s a lot. Let’s review the basics.

- Start the design for manufacturing process early. You don’t want to promise a feature to customers that is not cost-effective to build

- Your initial designs can be hand-sketched and based off calculations before you spend a lot of time and money modeling and purchasing parts

- You might consider hiring an industrial designer to run a design review on your models before you start down a particular path. They can poke holes in your plan and raise DFM considerations related to manufacturability

- Have options when vetting contract manufacturing partners. Formalize a review process that respects both your time and that of the manufacturer

- You’ll need to make an up-front investment in tools that your manufacturer will use, and you may need to adjust tools down the road

- Create an assembly guide for both you and your manufacturer

- Run your initial assembly onsite with your manufacturer (if possible) to oversee their first assembly

- Decide if your contact manufacturer will ship to you direct or ship to a warehouse

It’s important to have a basic understanding of the forms, materials, and processes available to you at the very early stages of product design. This will help guide what is and is not possible for your product before you spend a lot of time and money trying to build it and get it in front of customers. Once you understand the driving forces and limitations around the manufacturability of your product, you can enter an intense iterative prototyping phase, where you’ll circle back to DFM as you address particular product features and parts. Laying this groundwork will allow you to seamlessly vet and hire a contract manufacturing partner without having to aggressively re-design a portion or all of your product.

If you need help with either the design or contract manufacturing hiring process, mHUB offers a variety of resources including access to contractors and even full contract R&D services that can guide you through each step. mHUB Members also gain access to several Experts in Residence, so if you have questions about contract manufacturers, talking with an EIR with a supply chain specialty would be advantageous. Review mHUB membership options to learn how you can gain access to mentors, EIRs, and other critical resources that further support the launch and scaling of your physical product idea.